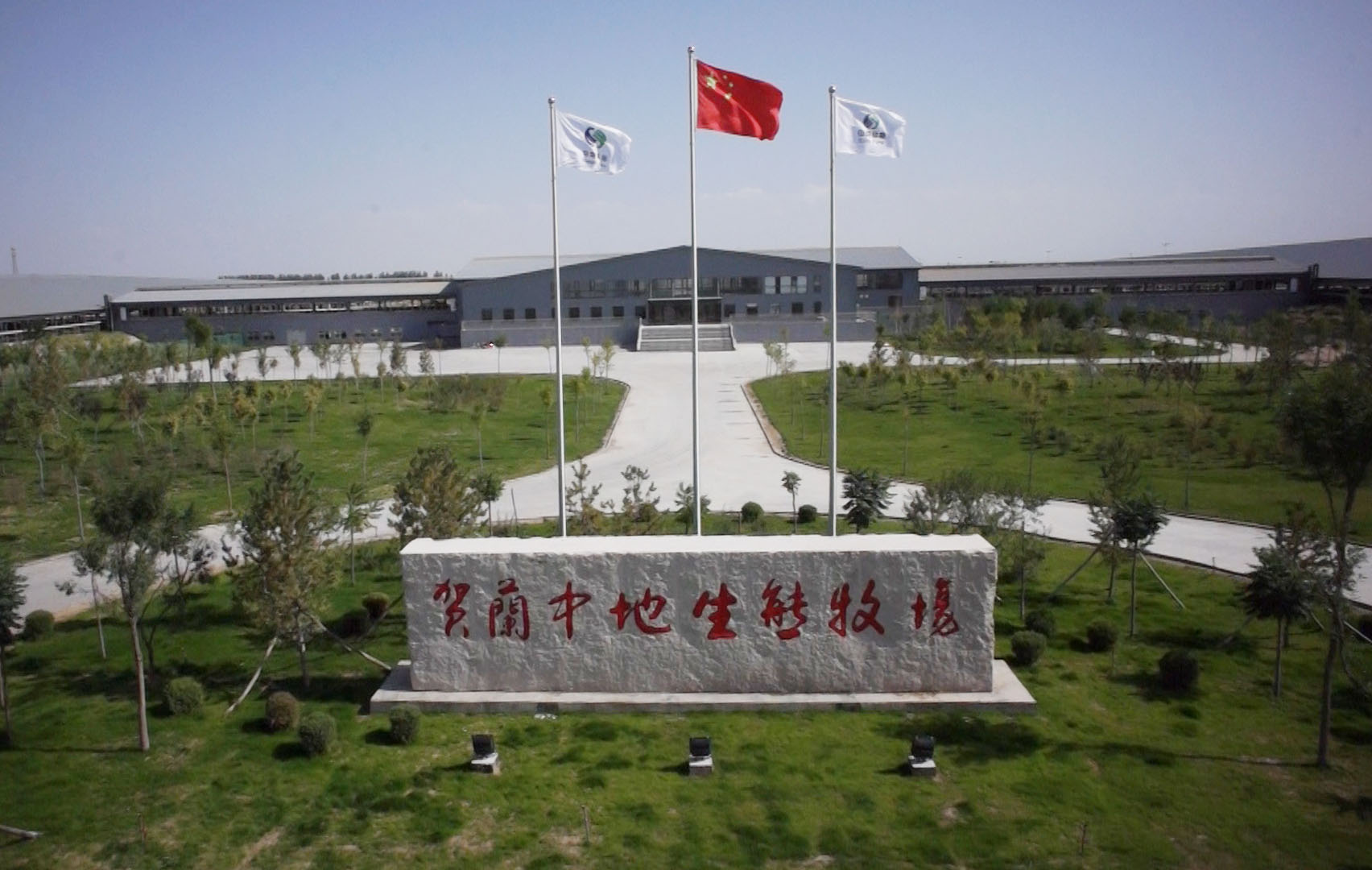

Huolongmen Ranch is a domestic super-large farmland invested by Heihe Zhongxing Animal Husbandry Co., Ltd., located in Huolongmen Town, Nenjiang County, with a scale of 14,000 cows. Construction began in April 2014 and the first batch of dairy cows was introduced in November. In 2014, the acceptance of 100 standard demonstration ranch projects in Heilongjiang Province was the first in the province.

The layout of the pasture adopts the most advanced design concept in the world. The construction standards are based on the construction specifications of the provincial modern dairy farm. The most scientific production technology in the world is adopted. The machinery and equipment will be purchased from well-known brands at home and abroad. The dairy cow was imported from Chile and NZ, the farm is equipped with 2 Afghan 84 rotary milking machines, using Affijin Ranch management software, automatic feeding center, cow automatic feeding system, Austria solid-liquid separation processing system, US manure Processing system, Shanghai Najie Power Control System.

The pasture planning is divided into four major areas: 1. The production management area includes comprehensive buildings and buildings related to production and operation; 2. The auxiliary production areas mainly include water supply, power supply, heating, maintenance, silage, and grass storage; 3.The production area mainly includes cowsheds, milking parlors, artificial insemination and laboratory buildings; 4. Manure treatment and sick animal isolation areas mainly include veterinary rooms, isolation barns, sick cattle treatment and manure storage and treatment facilities.

There are 9 departments in the pasture for feeding, breeding, veterinary, milking, cow, information, synthesis, equipment and cattle.

The dormitory is a 6-person room, 24 hours of hot water supply, internet access, reading room, activity room, billiards room, table tennis room, bathroom, laundry room and other facilities.

As of October 26, 2015, there are 180 employees in the ranch. The total number of cattle in the farm is 8,265. In 2015, the silage planting area was 1,700 hectares, and a total of 85,000 tons was acquired. Production began in September 2015. It is estimated that by the end of 2015, a total of 4,069 heads cow will be produced, and the total number of cattle will exceed 10,000. It is expected that milk production will reach 180 tons. It is estimated that by May 2016, the number of employees will increase to 300, and the total number of cattle will exceed 12,000.

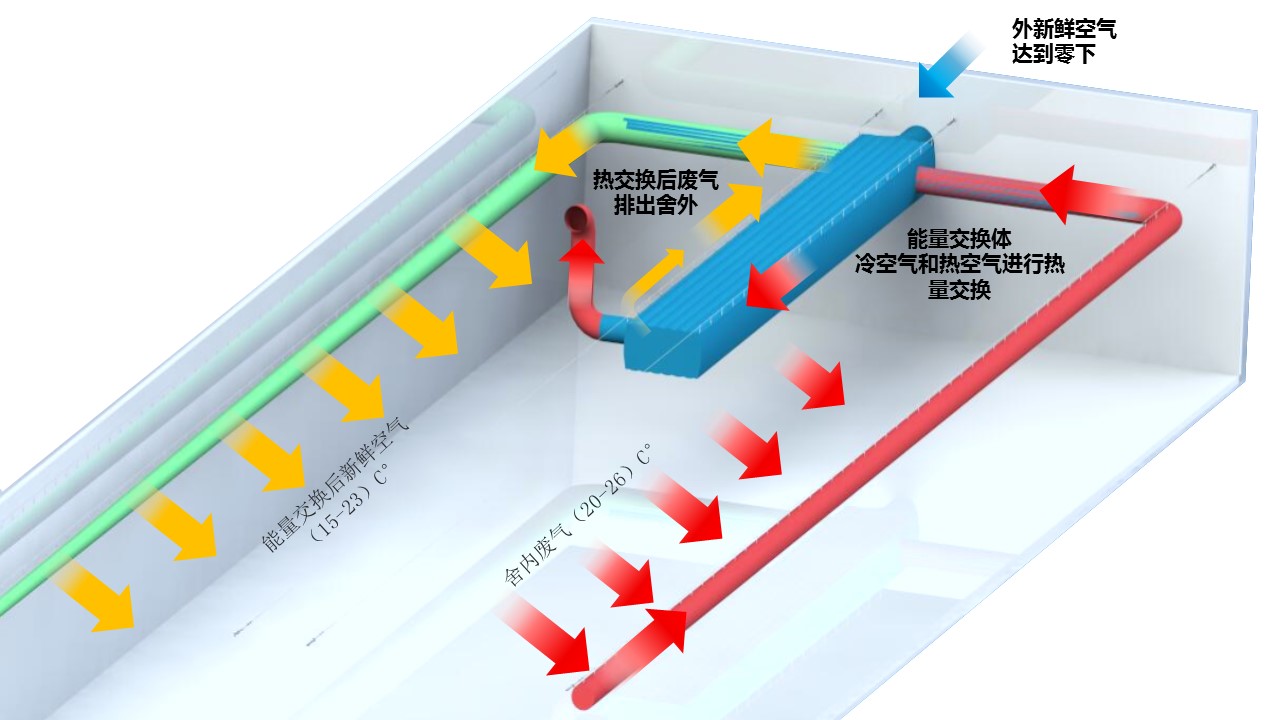

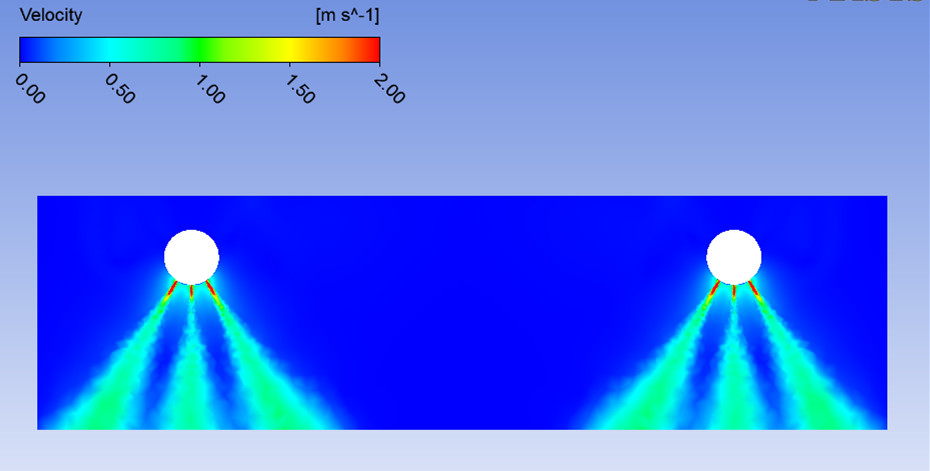

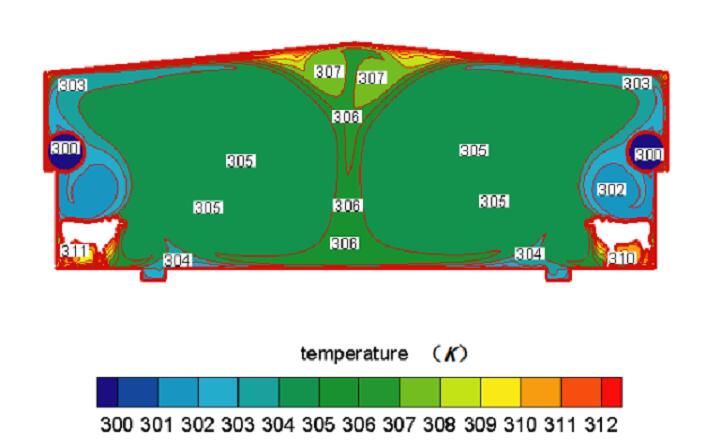

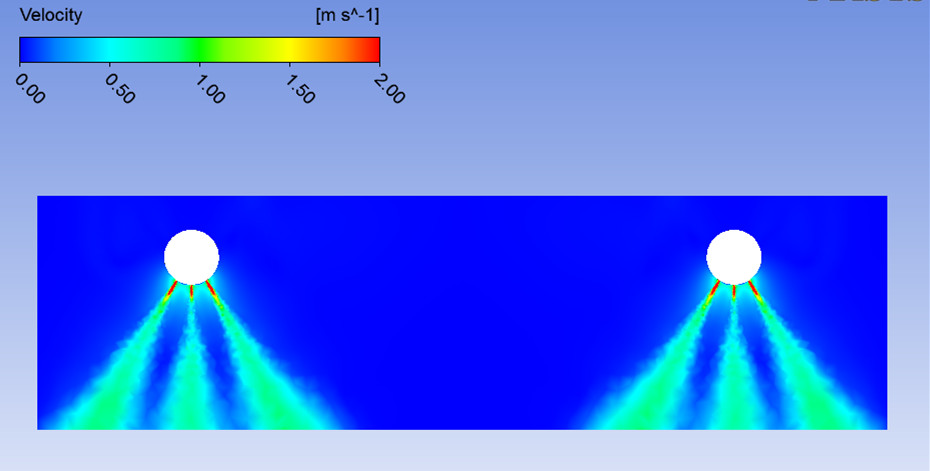

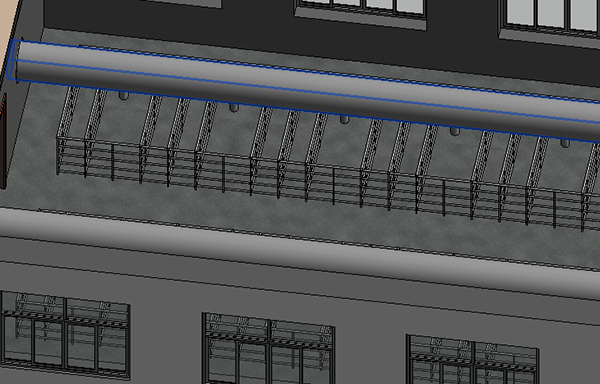

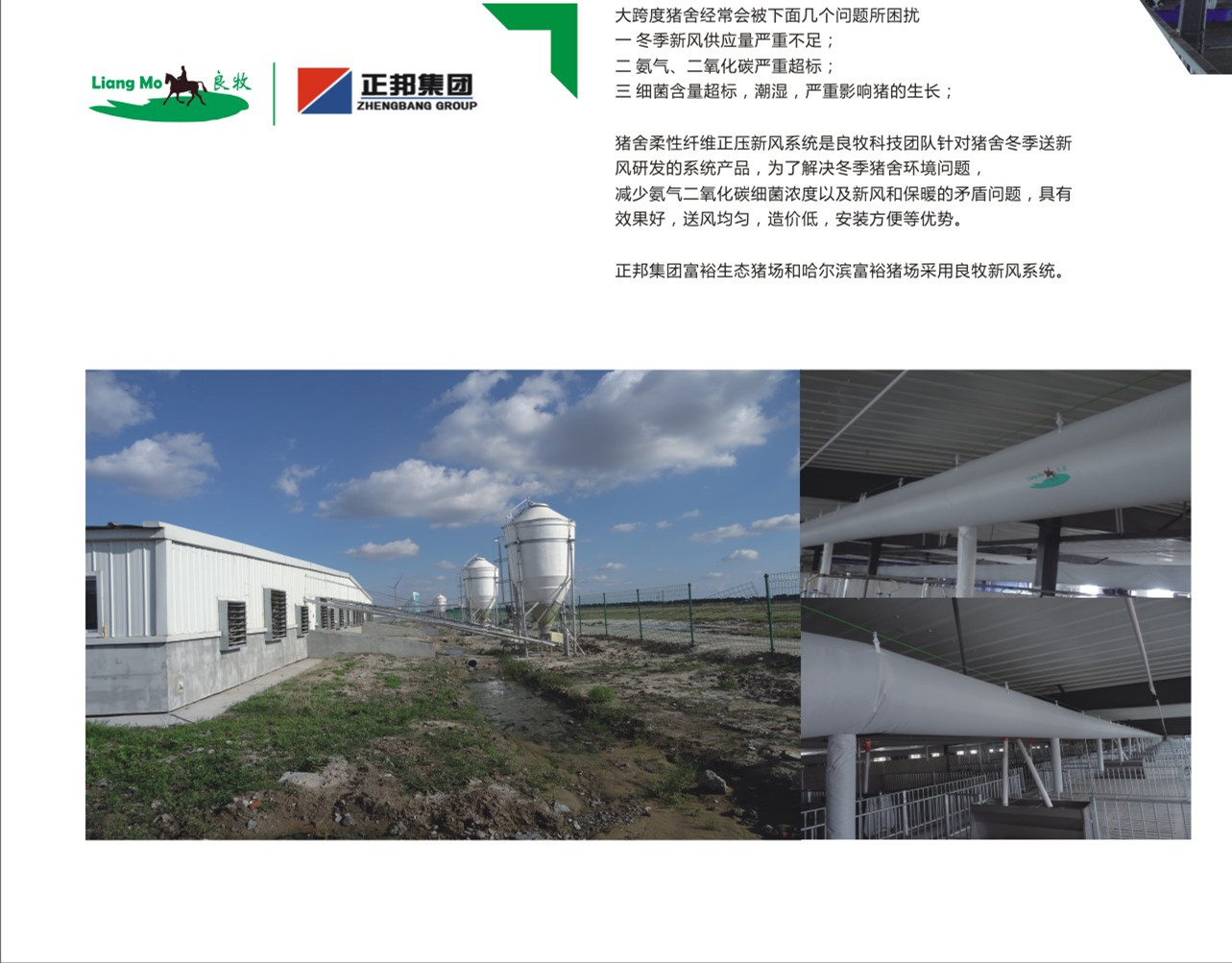

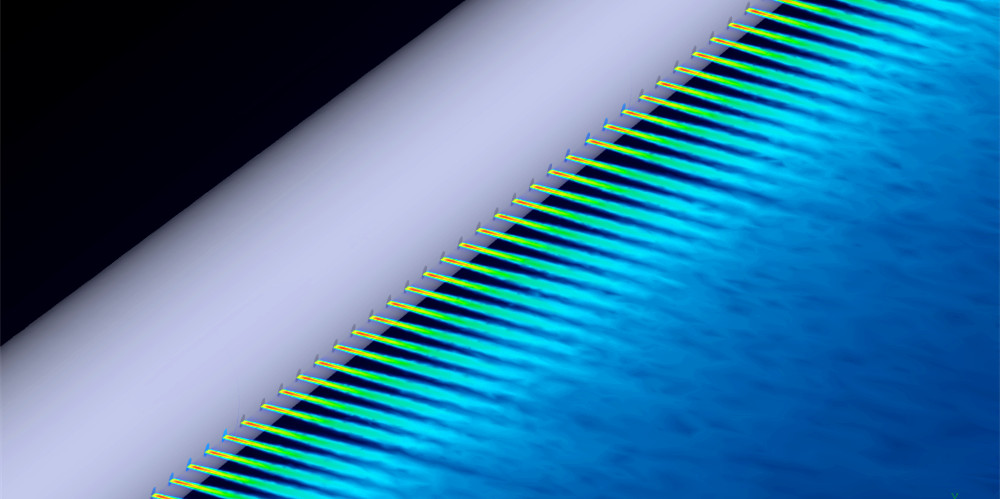

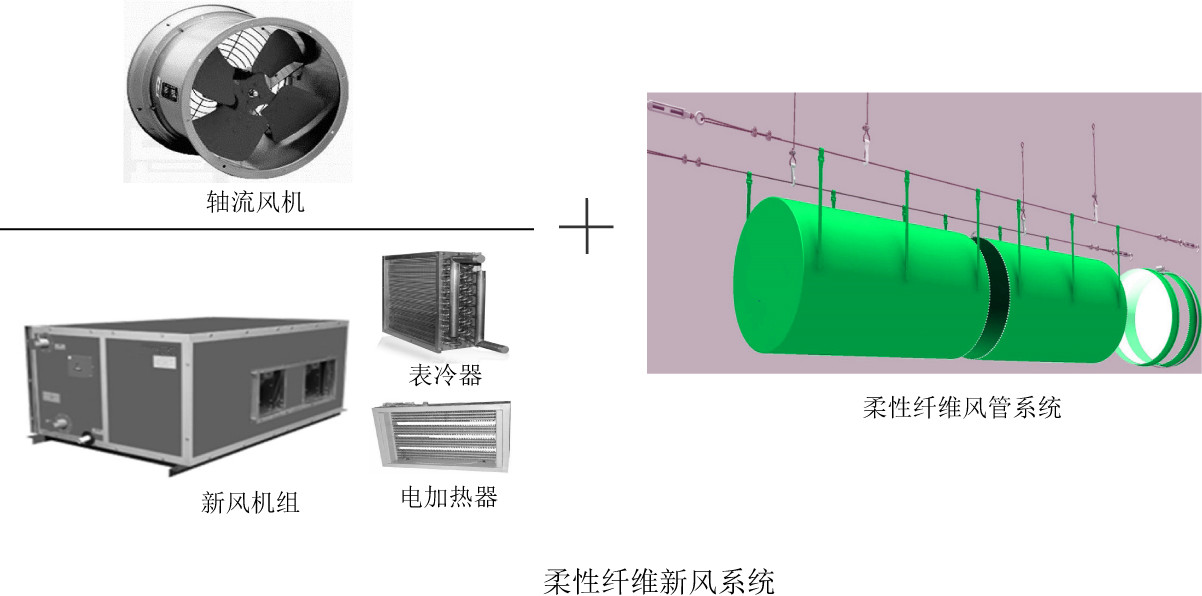

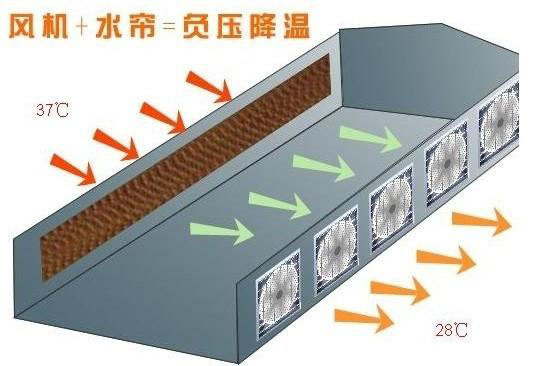

The purpose of the positive pressure ventilation of the flexible fabric cloth duct is to exchange the clean air of the wilderness into the cow house through a special ventilation system to dilute and discharge the dirty air in the cow house. The positive pressure ventilation system is mainly composed of an intake fan and a long ventilation duct that is full of many vent holes. The intake fan is placed at the intake port of the house end, and the function is to exchange the clean air outside the house; the long ventilation duct is hung on the top of the cow house, and its length is almost equal to the vertical axis of the cow house. A plurality of venting holes are arranged to allow the cleaned outside air to escape evenly.

The basic working principle of the positive pressure ventilation system: the external clean air is exchanged by the intake fan, and the clean air is evenly released through a long ventilation duct which evenly arranges a plurality of venting holes through the entire cow house, thereby diluting and discharging dirty air inside.